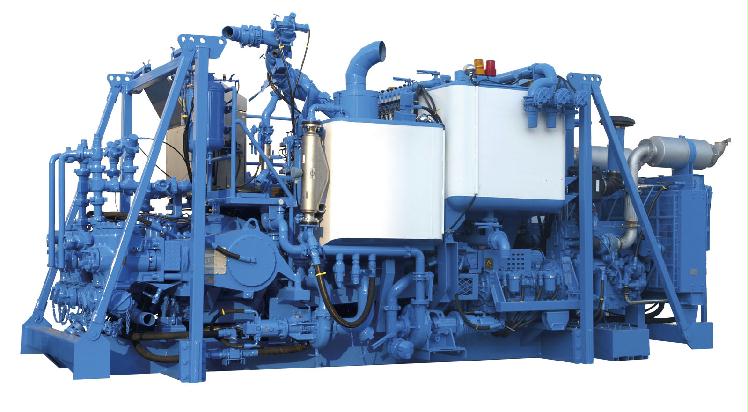

PCS-522 Remote Control Explosion proof Dual pump Cementing

Skid has the operation capacity in the hazardous gas source

environment. Such equipment is mainly used for the offshore

oilfield cementing operation, acidization treatments and oil

well pressure test in the explosion proof grade ZONE-II area.

‒ Add the human-friendly design: sound-proof unit;

‒ Remote control: the automatic control level is significantly

improved;

‒ Meet ZONE-II area explosion proof;

‒ Certified by ABS-CDS/DNV, meet the international operation

requirements, qualified to operate oversea.

Specifications

| Engine |

CAT C15 explosion proof, 530 HP @ 2100 RPM , 2 sets

|

| Transmission |

ALLISION 4700 OFS explosion proof , 5 forward gears

+neutral position , 2 sets

|

| Cementing pump |

SJS TPH400 , plunger size: 4.5" and 4" , 2 sets |

Three-cylinder plunger pump

| Model |

TPH 400, reciprocating, horizontal, single-action

plunger pump

|

| Stroke |

8"(203.2mm) |

| Rated pressure |

76.2 MPA @4.5″plunger ; 103.4 MPA @4″plunger |

| Maximum displacement |

1.52 m3/min @4.5″plunger ; 1.20 m3/min @4″plunger

|

ACM slurry mixing system

| Mixer |

High energy re-circulating mixer |

| Mixing water pump |

Mission 4X3 X13; 1.65 m3/min @ 0.78MPa ;2 sets |

| Circulating pump/booster pump |

SJS 6X5 X11; 3.70 m3/min @ 0.45MPa; 2 sets |

| Densimeter |

Micro Motion non-radioactive densimeter |

Other

| Slurry mixer skid |

7.5BBL |

| Displacement tank |

2 X 10 BBL |

| Explosion proof system |

3GP system, 1 set |