Introduction:

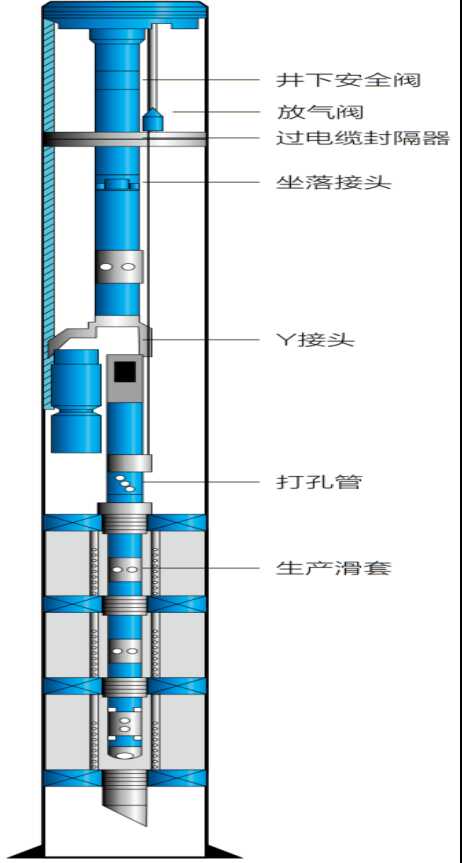

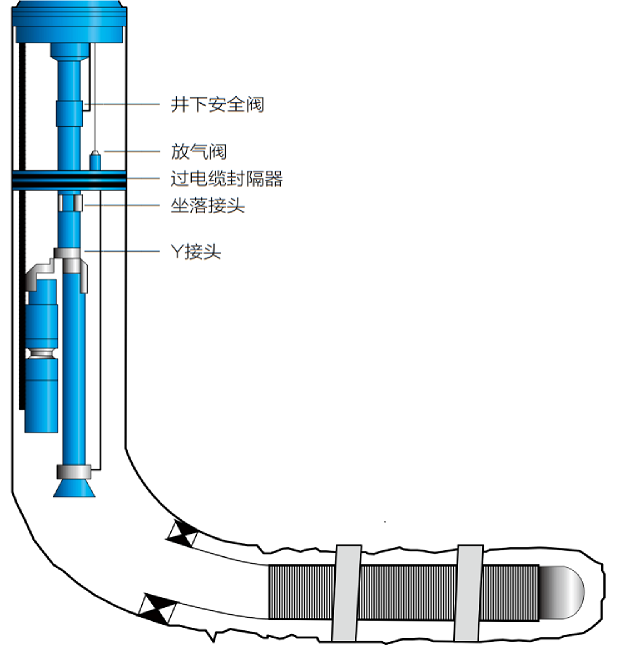

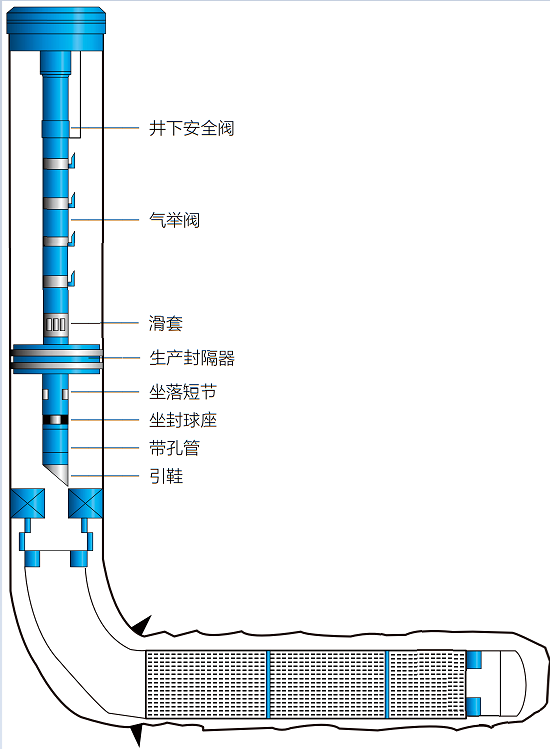

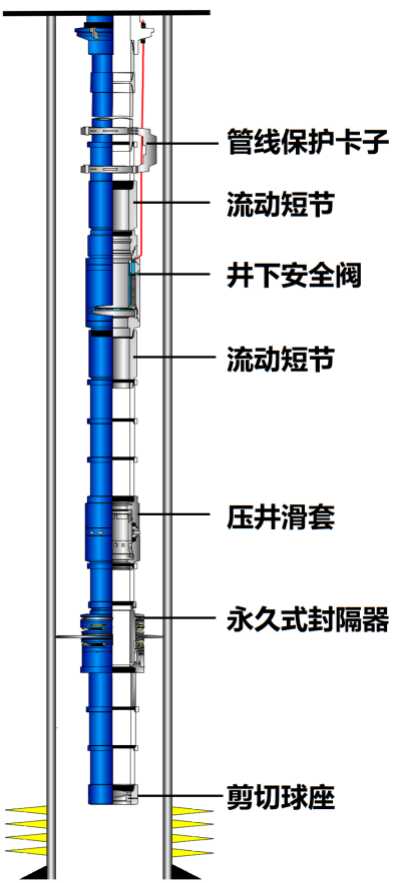

Y-shape separated production string and Y-shape commingled production string are the common completion strings for ESP artificial lift. Y-shape commingled production string configuration is simple and easy to be operated, allowing the production of multiple layers at the same time when the pressure condition and fluid properties are similar. Y-shape separated production string is designated for separated production of single layer of multilayer zones, uncontrolled commingled production and controlled commingled production, it is commonly conducted through slick line operation.

The oil well can be directly produced by flowing, if the flowing capability allows during the early stage of development. The use of electric submersible pumps for artificial lift oil production has the advantages of large liquid discharge, high wellhead pressure, requires less surface equipment, and therefore small foot space. It is the main method of artificial lifting in offshore oil fields development.

String:

Related pictures: